News

One of the world’s most complex underground tunnel networks protected by a Pertronic system

Tweet

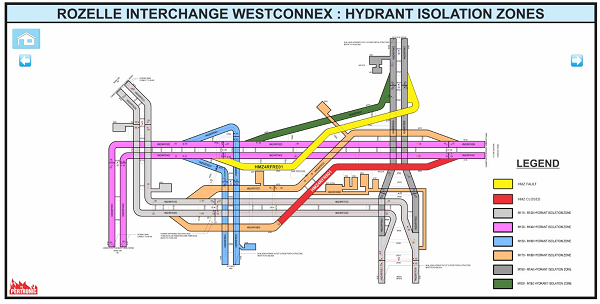

Coping with a complex network of more than 16 kilometres of drivable tunnels, four tunnel portal structures, 12 bridges and two ventilation facilities has been part and parcel of Pertronic’s contribution to Sydney’s Rozelle Interchange.

Rozelle, which opened in late November 2023, is regarded as one of the world’s largest and most complex underground junctions.

Also described as a ‘spaghetti junction’ it consists of two parallel sets of main tunnels across three storeys, with the deepest being 65m underground. Rozelle is the final stage of Sydney’s WestConnex project providing 33km of new motorways to link the city’s western suburbs with the CBD and airport.

The key elements of the A$4.6 billion Rozelle project for all participants, including Pertronic’s fire detection and protection system, relate to a nest of merging and diverging carriageways. Such configurations have major impacts on the designs allowing safe occupant (motorist) egress, fire brigade access and intervention, and fire control.

A Pertronic F220 panel, wired to deluge hydrants

Among some of the fire protection statistics associated with Rozelle are:

- Number of main panels – 3

- Total number of panels on the Rozelle site – 153

- Number of deluge systems (driven by Pertronic panels) – 555

- Number of Modbus interfaces – 6

- Number of GUI’s (Graphic User Interface) – 6

- Longest fibre run to the St Peter’s control centre – 16km

- Total number of system network points – 64,089

- Total number of FireMaps® - 283

In addition the integrated Pertronic system has 18 ASE (Alarm Signaling Equipment) units which communicate with 24 fire brigade inputs. In the event of a fire, the brigades will be directed to the most appropriate entry point for a specific alarm. A hierarchal system has also been established for deluge control sitting alongside (an operator-controlled) motorised valve operation.

The entire project required detailed discussions between the installer contractor and Pertronic personnel. As well as reaching an agreement on design specifications, all parties were made fully aware of lead times, parts’ availability and system programming requirements.

An important contribution to the interaction with all participants was the setting up of a Rozelle emulation site at Pertronic headquarters.

By linking 153 panels, and subjecting them to different input and output stresses, a total reassurance was established that the entire network could handle whatever load it may have to handle, and that is would have complete reliability. This is one of the advantages of having an in-house research and development team – which in this case was a group of engineers attempting to ‘break’ the network, but being unable to do so.

Since its commission, Rozelle’s entire fire protection system has demonstrated the soundness proven in the emulation tests.

CLICK to CALL US NOW

CLICK to CALL US NOW